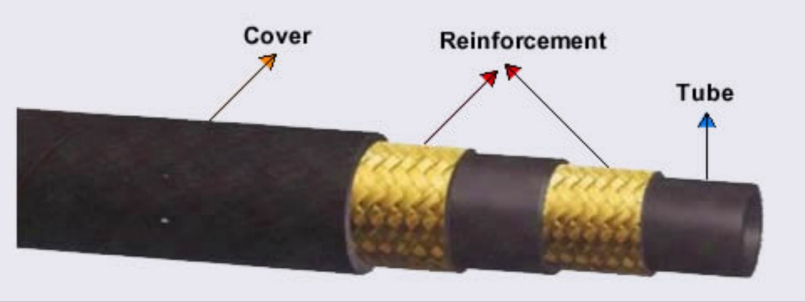

Hydraulic rubber hoses are getting popular in conveying hydraulic fluids with pressure for their great flexibility, affordability and durability. General speaking, a hydraulic hose consists at least three parts - an inner tube which carries the fluid, a reinforcement supporting the tube and an abrasion and ozone resistant cover.

Inner tube should be compatible with the fluids it will carry and have some flexibility. Common materials of making tube are synthetic rubber, thermoplastics and PTFE. They are friendly to most petroleum- and water-based hydraulic fluids. If the tube reacts with the fluids, the hose will be prone to leakage or cause incidents. When you are not sure about the relationship between the tube and the media to be carried, consult us and we will come back to you soon.

Hose reinforcement is taken as a sheath protecting fragile tube. It is used to be multiple layers of braided textile, wire or spiral-wound wire. They can support different grades of pressures according to your applications. Commonly, textile reinforcement, whether single or double layers, is ideal for tight routing and low pressure system such as return and suction systems. Braid wire and spiral wire are usually for high working pressure. If the system has severe requirement of impulse fatigue, spiral wire reinforcement is the priority.

Cover is the first barrier to guard the hose. It is usually made of abrasion and weather proof synthetic rubber to resist oils, chemicals, ozone and other adverse factors from outside environment.

Need any help?

Contact Us

DIN EN 857 SC Wire Braid Reinforced Compact Hydraulic Hose

What can we help you with?

Feel safe and free to fill in the form! We do not sell, trade or transfer your personally identifiable information to any external parties.

Contact Us

No.11 Yangshan Road,Shaoling District,Luohe City,China

+86-3953287955

Submit Request